Jaw crusher is the emergence earlier crushing equipment, because of its simple structure, strong, reliable work, easy to maintain and repair and production and construction costs less, therefore, until now is still widely used in metallurgy, chemical industry, building materials, electric power, transportation and other industrial sectors, compressive strength at 147-245MPa for various ores and rocks of coarse, …

【 What's a jaw crusher ?】A jaw crusher is a compression type crusher, usually used as a primary crusher set at the very front of the ore or rock crushing plant to reduce hard rock size.

Better throughput and reduced cost - TST Jaw Crusher Optimise your business with improved output, reduced repair and replacement costs and better monitoring. Our TST Jaw Crusher builds upon more than a century's worth of FLSmidth experience to give you a crushing solution you can trust to get the job done, and to do it right.

Mobile jaw crusher eliminates the obstacles brought by the crushing field and environment, which greatly broadens the concept of crushing operations, so as to really provide high efficiency and low cost operation project for customers, which is a new series of rock crushing equipment.

Stationary jaw crushers Sandvik jaw crushers are of the single-toggle type with advanced features for optimized performance, easy maintenance, long life and a low cost per ton.

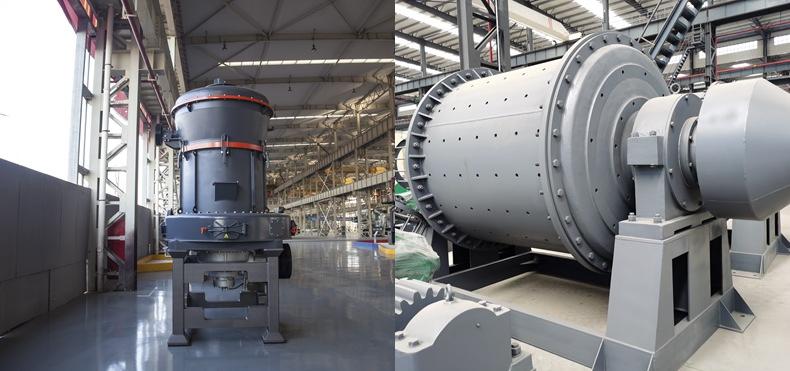

Jaw crusher is the common mechanical equipment for processing the mineral ores, whose production capacity is much bigger than that of the other crusher while it can process various mineral ores. Ball Mill. Processing capacity: 0.5–500 t/h. Feeding size: ≤25 mm. Rotary Dryer.

Jaw crusher is one of the most popular crushing equipment in the international market at present, which is mainly used for middle size crushing of various mineral orcs and bigger materials with compression strength less the 320Mpa. with the national advanced level, we are mainly focused on the production of large and middle type Jaw Crusher.

Jaw crusher definition is - a machine for crushing rock or ore between two heavy steel jaws.

Introduction The European type jaw crusher is generally used in primary crushing and medium crushing of ore and rock whose compressive strength does not exceed 280 MPa, especially suitable for hard and highly corrosive materials.

Essa JC2000 Jaw Crusher . The Essa JC2000 Jaw Crusher is known as a "workhorse" in the industry, and for good reason. It is dependable, hard-wearing, and has proven itself in exploration and grade …

Jaw Crusher Flywheel Rotational energy is fed into the jaw crusher eccentric shaft by means of a sheave pulley which usually has multiple V-belt grooves. In addition to turning the pitman eccentric shaft, it usually has a substantial mass to help maintain rotational inertia as the jaw crushes material. Jaw Crusher Tension Rod

The jaw crusher,also called jaw breaker,is a kind of stone crusher machine,which is widely used in mining, building materials, chemical industry, metallurgy and so on.

China Jaw Crusher. 1.2K likes. Jaw crusher, both small and large capacity, from 10 to 1000 ton per hour

The Essa JC1000 Jaw Crusher is the smallest of the range. It is a medium-duty, entry-level machine designed for crushing smaller samples across a wide range of applications. Known in the industry as a steady-going and reliable machine, it is productive and hardy, with reduced operating and spare parts costs. Simple and compact design

Retsch Jaw Crushers are used for the rapid, powerful crushing and pre-crushing of mediumhard, hard, brittle and tough materials. The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants. Jaw Crusher BB 50 Feed material: medium-hard, hard, brittle, tough

A jaw crusher robustly constructed single-toggle type with one fixed jaw plate and one moving jaw plate. Designed for the smaller laboratory, or use by prospectors. It is capable of quickly crushing materials …

Goldbelt Global OLESI Jaw Crusher hard rock mining sampling lab assaying . $899.00. $88.41 shipping. 58 watching. Small Jaw Rock Crusher Gold Mining 911Metallurgist. $1,400.00. $49.72 shipping. or Best Offer. 17 watching. 1997 ELRUS 2036 Jaw Crusher. $40,000.00. Local Pickup. or …

The jaw crusher is widely used in mining, building materials, chemical industry, metallurgy and so on.

Mobile jaw crushers We are committed to producing the very best in specialized mining and rock excavation equipment. Our pioneering mobile jaw crusher series is a powerful example.

MRB Engineering Works is a leading manufacturer and Supplying a wide range of Jaw Crusher Machine, Stone Crusher Machine, Industrial Vibration Screen, Jaw …

Introduction Jaw crusher (Blake Jaw Crusher) can be used in coarse crushing, medium crushing and fine crushing of raw materials. The working method of the jaw crusher machine is laminating crushing and it has advantages of high crushing ratio, uniform particle size, simple structure, reliable operation and easy maintenance, etc.

Introduction Jaw crusher (Blake Jaw Crusher) can be used in coarse crushing, medium crushing and fine crushing of raw materials. The working method of the jaw crusher machine is laminating crushing …

What is a Jaw Crusher? A jaw crusher is a compression type crusher, comprised of a fixed jaw and moving jaw positioned in a (V). The movable jaw compresses material against the fixed jaw, crushing the material to the desired size. The material exits the jaw through the bottom of the crusher otherwise, known as the discharge opening.

A Jaw Crusher reduces large size rocks or ore by placing the rock into compression. A fixed jaw, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate.

Jawcrusher definition: a device having hinged jaws for crushing rocks and ores | Meaning, pronunciation, translations and examples

Nov 13, 2017· This jaw crusher has one stationary and one movable jaw, with the motion greater at the top than at the bottom. Compressive force plays a role in crushing the particles. The material being …

Jaw crusher can be divided into large, medium and small sizes. The crusher with above 600MM feeding mouth is the large crusher, 300-600MM is medium crusher and less than 300MM is small jaw crusher.

Jaw Crusher Flywheel Rotational energy is fed into the jaw crusher eccentric shaft by means of a sheave pulley which usually has multiple V-belt grooves. In addition to turning the pitman eccentric shaft, it usually has a substantial mass to help maintain rotational inertia as the jaw crushes material. Jaw Crusher …

Jawcrusher definition: a device having hinged jaws for crushing rocks and ores | Meaning, pronunciation, translations and examples

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan's Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers.